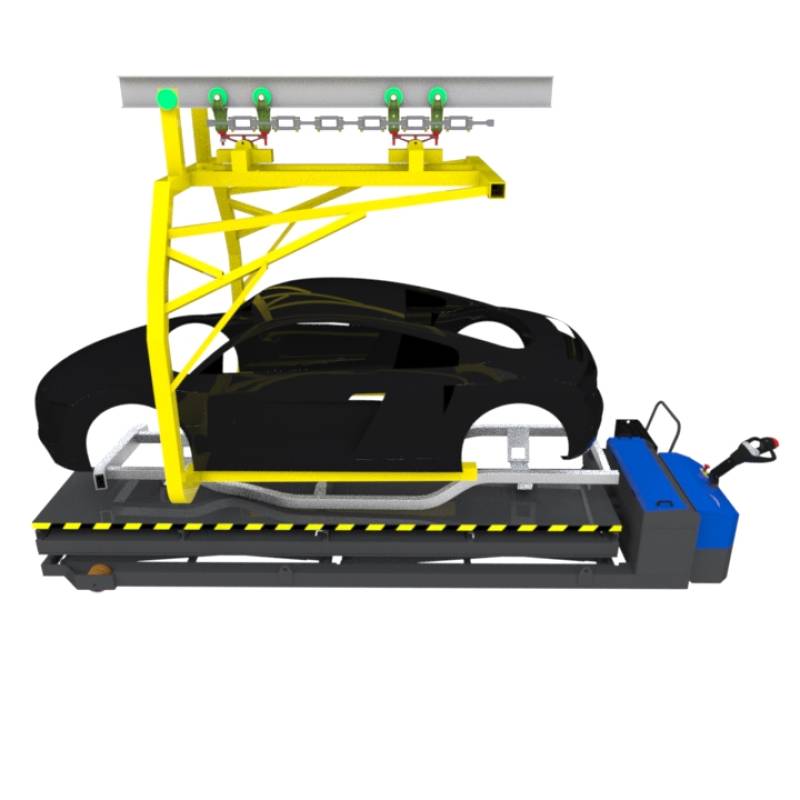

TEM HL AC-evo Special - Lift Table for Prototyping Department

Motorized lift tables are used in the automotive sector, particularly in the prototyping department, to perform the "marriage" operation, which is the joining of the chassis with the bodywork and to check for any incompatibilities or modifications needed before production launch. During prototyping, this operation must be performed multiple times on the same vehicle, so it's not possible to create an automated system like the production lines. Thanks to this table, the operator can position themselves under the prototype bodywork and lift the chassis to complete the joining with minimal effort and maximum precision, in full compliance with safety regulations. This product can be customized in terms of platform dimensions, lifting stroke, and capacity. The tiller can be equipped with power steering upon request or integrated with wireless remote control. For solutions with higher capacity, the oscillating traction unit, separate from the lifting frame, always ensures maximum traction even on uneven flooring.

Request information